After being unstaffed for a considerable period of time. Peterborough Nene Valley has been brought back to life over the last few years by a small team of volunteers led by Tony King formed from the Platform Staff and assisted by other departments at the Railway.

The Station plays an important role at the Railway as the entrance point and first impression for the majority of our passengers who use public transport to visit the Railway as well as many city based visiting passengers, especially with its location within the city and next door to our friends at Railworld. The Wagon Group can often be seen at weekends working on various items of Freight Rolling Stock as well.

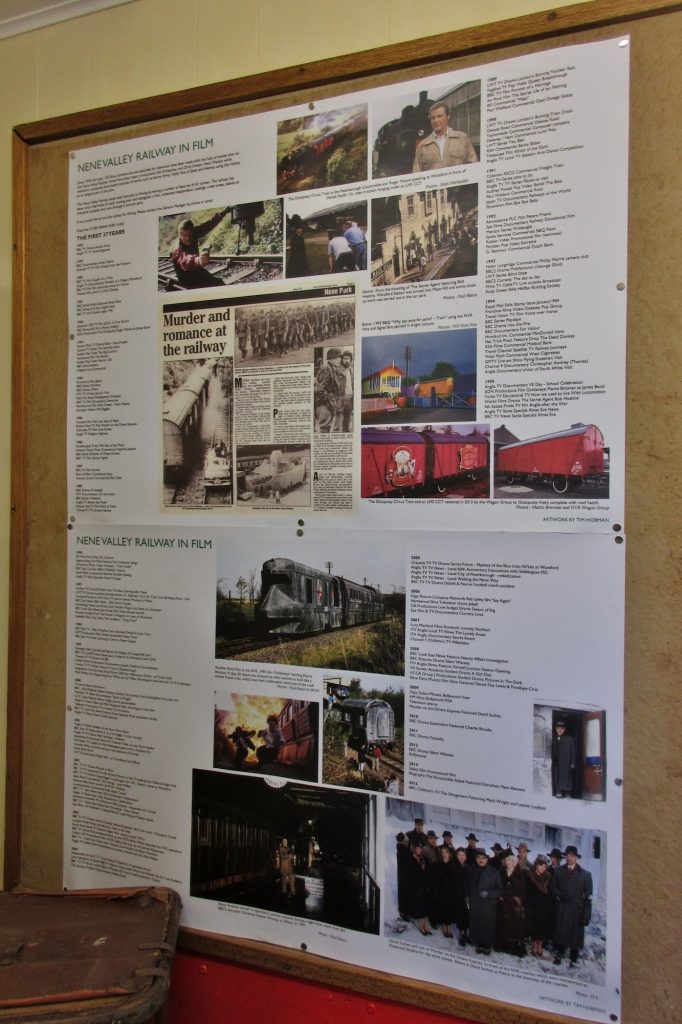

As you can see from the pictures, a lot of work has gone on to develop the appearance of the site and the Station is manned on running days now which enhances the visitor and volunteer experience. Inside the building we have developed information boards about the railways history both as part of the network and the preservation movement, the railway history of what the site used to be, (it was a loco shed and yard and not a station), we’ve also got may little artefacts of various sorts of heritage and railway history

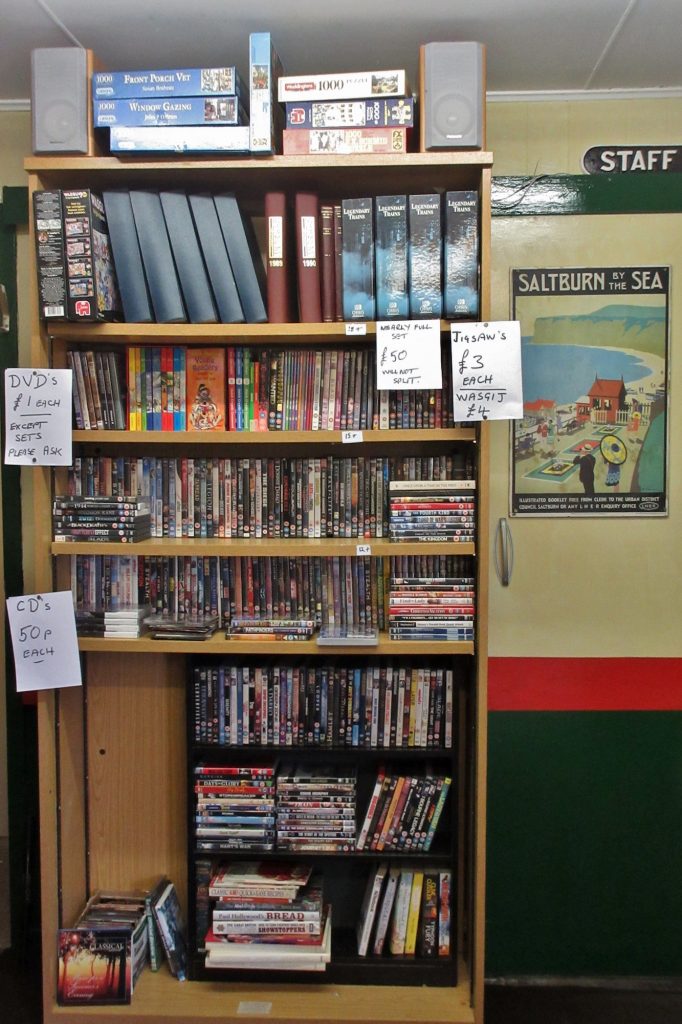

We fundraise to develop the site ourselves, largely through the sale of books, dvd’s and jigsaws and have been very successful so far, the next job will be to replace the daggerboards outside the building to enhance it even further. We don’t charge for Platform Tickets so come along and have a look on a running day and chat with the volunteers and all donations in terms of things to sell or financial in person are always most welcome as we work to make PNV even better for all and demonstrate our pride in the NVR!

Thomas Woolley.